Project: Velsertunnel Renovation Agency: Ministry of Infrastructure and the Environment Location: Velsen, Netherlands Software: Recap, AutoCAD, Revit Structure, Civil3D, InfraWorks 360, 3D Studio MAX, Navisworks Manage

Vertical and horizontal BIM for historical landmark in Velsen,Netherlands

Opened in 1957, the Velsertunnel is a railway and motorway tunnel beneath the North Sea Canal in the Netherlands. Rijkswaterstaat, the Dutch government’s Ministry of Infrastructure and the Environment, is in the midst of renovating the automobile section of this aging tunnel. The renovated tunnel will have a higher clearance profile for trucks, new asphalt, and new, modern technical installations, such as CCTV, fire protection equipment, traffic control systems, and ventilation. The escape routes will also be fully updated.

Approx. 65.000 vehicles per day pass through this tunnel and during renovation period it will be closed for 9 months. The renovated tunnel will have a higher clearance profile (>12 cm), renewed asphalt and new state-of-the-art technical installations (e.g. CCTV, fire protection equipment, traffic control systems, ventilation, etc.). The escape routes will also be fully optimized and renewed.

In 2014, Rijkswaterstaat awarded a design/build/maintain contract for the project to Hyacint, a consortium of BESIX, Dura Vermeer, and SPIE, supported by iNFRANEA.

Project challenges

The most unique engineering challenge of this project is to improve a 60-year old highway tunnel, in order to meet modern and unique requirements on specific European tunnel safety rules. The construction itself, including service buildings and ventilations shafts, will not be changed as the typical ventilations shafts are listed in the TOP 100 of Dutch monuments since the rebuilding period 1940 – 1958 and are listed as well as a National Heritage since 2014.

Project details

Model-based workflows

The model-based approach increases efficiency within individual organizations and provided big benefits during coordinated project delivery.

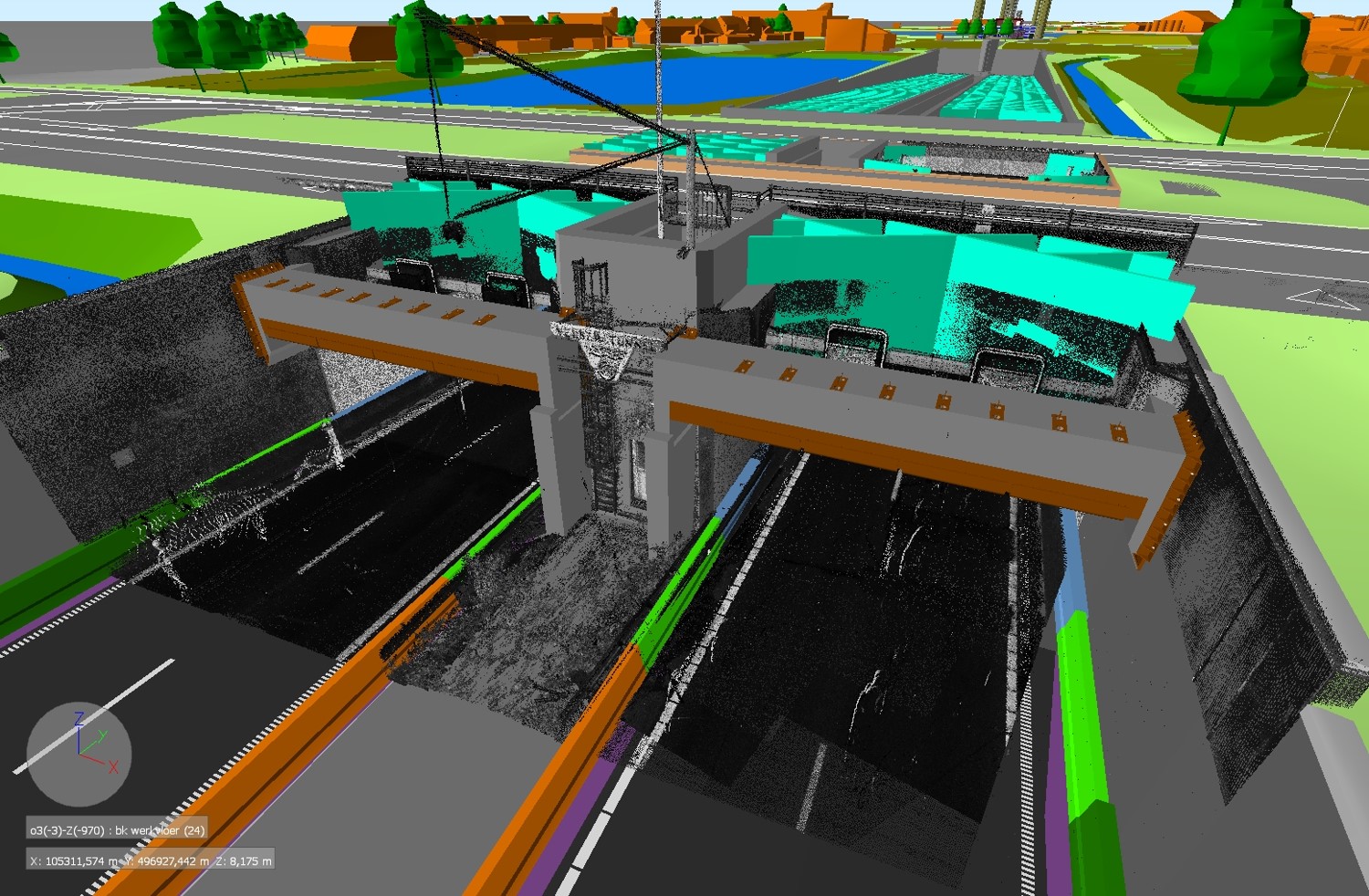

Scanned data of the existing tunnel and service buildings was combined with aerial photography and terrain models to create precise 3D models of existing conditions for its design.

- Compiling input of point clouds, digital elevations and aerial mapping into a single integrated model gave advantages during the preparation stage of the BIM process.

- Model-based design processes are increasing design quality and efficiency, and improving project coordination and communication.

- The integrated model provided more information than drawings. By integrating our BIM processes by means of an intelligent semantic database, we allowed each discipline to connect their particular intelligence to the models. Requirement- and interface management (incl. automated clash-detections), along with document management, all became an integral part of the processes. The semantic database also supports LEAN processes including management of tasks, issues and changes…

Leave a Comment

You must be logged in to post a comment.